Aluminium

Aluminum is a versatile and widely used metal renowned for its lightweight yet robust properties. It is the third most abundant element in the Earth’s crust, making it economically viable and environmentally sustainable. Aluminum possesses excellent corrosion resistance due to its ability to form a protective oxide layer when exposed to air, making it suitable for various applications in diverse industries.

In manufacturing, aluminum is valued for its high strength-to-weight ratio, making it ideal for aerospace components, automotive parts, and structural materials in buildings and bridges. Its malleability allows it to be easily formed into complex shapes, enhancing design flexibility and reducing production costs. Moreover, aluminum’s conductivity makes it indispensable in electrical transmission lines and components where efficient energy transfer is essential.

The metal’s recyclability is another significant advantage, as it can be recycled repeatedly without losing its inherent properties. This characteristic not only conserves energy but also reduces greenhouse gas emissions associated with primary aluminum production. As a result, aluminum plays a pivotal role in sustainable manufacturing practices and circular economy initiatives worldwide.

From everyday consumer goods to advanced technological applications, aluminum’s versatility and durability make it a cornerstone of modern industrial processes, contributing to innovations in transportation, construction, electronics, and packaging sectors globally.

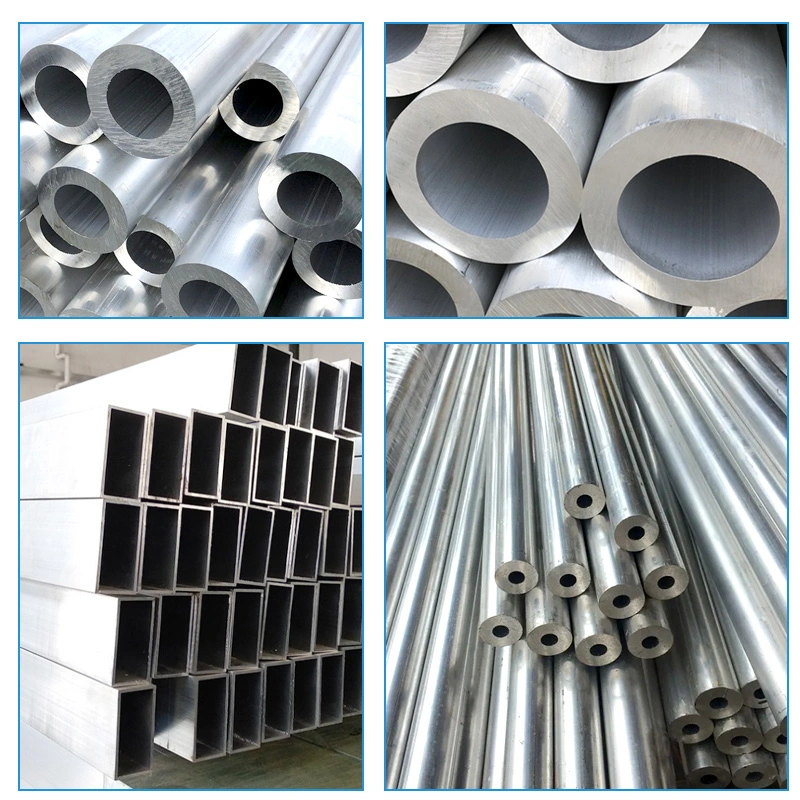

Aluminum industrial products are integral to a wide range of sectors due to their unique combination of properties such as light weight, high strength, and resistance to corrosion. These products include sheets, plates, foils, bars, rods, tubes, and extrusions, each tailored to meet specific industrial needs. Aluminum sheets and plates are extensively used in the aerospace and automotive industries for manufacturing aircraft skins, automotive panels, and other structural components. The light weight of aluminum contributes to fuel efficiency and performance in these industries. Aluminum foils find applications in packaging, insulation, and electrical industries due to their excellent barrier properties and conductivity. Bars and rods are commonly employed in construction and machinery, providing the necessary structural support and mechanical strength. Tubes and extrusions, which can be custom-shaped, are used in a variety of applications including HVAC systems, architectural frameworks, and transportation infrastructure.

The versatility of aluminum allows for easy fabrication and machining, making it a preferred choice for engineers and designers. Its recyclability is another significant advantage, aligning with sustainable practices and reducing environmental impact. The aluminum recycling process is energy-efficient, consuming only a fraction of the energy required to produce primary aluminum, thereby lowering carbon emissions. Innovations in aluminum alloying and treatment processes continue to expand its applications, enhancing properties like durability, conductivity, and thermal performance. Industries such as electronics, marine, and renewable energy are increasingly adopting aluminum products for their projects, underscoring the material’s critical role in modern industrial applications. In essence, aluminum industrial products not only contribute to the efficiency and sustainability of various industries but also drive technological advancements and economic growth.

At AG Industries, we focus on the best results of our products and services, and hence we provide our customers as per their requirements and standards. Every requirement is of utmost importance and is handled by responsible employees to deliver perfectly suitable solutions to various industries. We ensure that the stock is maintained in its adequacy and can be delivered to our customers as and when they demand. We offer a wide range of products with competitive prices. We look forward to a prompt response and timely delivery.

Aluminium Product Standard

| Standard | Description |

| ASTM A182 | Standard Specification for Stainless Steel Outlet Fittings |

| ANSI ASME B16.11 | Socket-welding and Threaded Outlet fittings |

| MSS SP 79 | Standard Specification for Stainless Steel Insert Welding Outlet |

| MSS SP-97 | SW,TH and BW ends for integrally reinforced forged branch outlet |

| JIS B2316 | socket-welding outlets pipe fittings |

Some Of Our Specialities That Make Us A Profitable Business Partner For Our Clients Are :

- Customer Focused Approach

- Superior Quality Products

- Timely Deliveries

- Customize Size & Specification

- Competitive Pricing

Applications Of Aluminium

| PROPERTY | METRIC | UNITS | ENGLISH | UNITS | ||

| General | ||||||

| Density | 2.5e3 – 2.9e3 | kg/m^3 | 156 – 181 | lb/ft^3 | ||

| Mechanical | ||||||

| Yield Strength | 3e7 – 5e8 | Pa | 4.35 – 72.5 | ksi | ||

| Tensile Strength | 5.8e7 – 5e8 | Pa | 8.41 – 79.8 | ksi | ||

| Elongation | 0.01 – 0.44 | % strain | % strain | |||

| Hardness (Vickers) | 1.18e8 – 1.48e9 | Pa | HV | |||

| Impact Strength (un-notched) | 1.9e5 – 2e5 | J/m^2 | ft.lbf/in^2 | |||

| Fracture Toughness | 2.2e7 – 3.5e7 | Pa/m^0.5 | 20 – 31.9 | ksi/in^0.5 | ||

| Young’s Modulus | 6.8e10 – 8.2e10 | Pa | 9.86 – 11.9 | 10^6 psi | ||

| Thermal | ||||||

| Max Service Temperature | 120 – 210 | °C | 248 – 410 | °F | ||

| Melting Temperature | 475 – 677 | °C | 887 – 1.25e3 | °F | ||

| Insulator or Conductor | Good | Conductor | Good Conductor | |||

| Specific Heat Capability | 857 – 990 | J/kg °C | 0.205 – 0.236 | BTU/lb. °F | ||

| Thermal Expansion Coefficient | 2.1e-5 – 2.4e-5 | strain/°C | 11.7 – 13.3 | µstrain/°F | ||

| Electrical | ||||||

| Insulator or Conductor | Good Conductor | °C | Good Conductor | °F | ||

| Electrical Resistivity | 2.5e-8 – 6.5e-8 | °C | 2.5 – 6.5 | °F | ||

| Eco | ||||||

| CO2 Footprint | 1.85 – 2.04 | kg/kg | 11.2 – 13.1 | lb/lb | ||

| Recyclable | Yes | Yes |